- Home

- >

- News

- >

- Light box graphic

- >

Light box graphic

2024-11-12 14:40

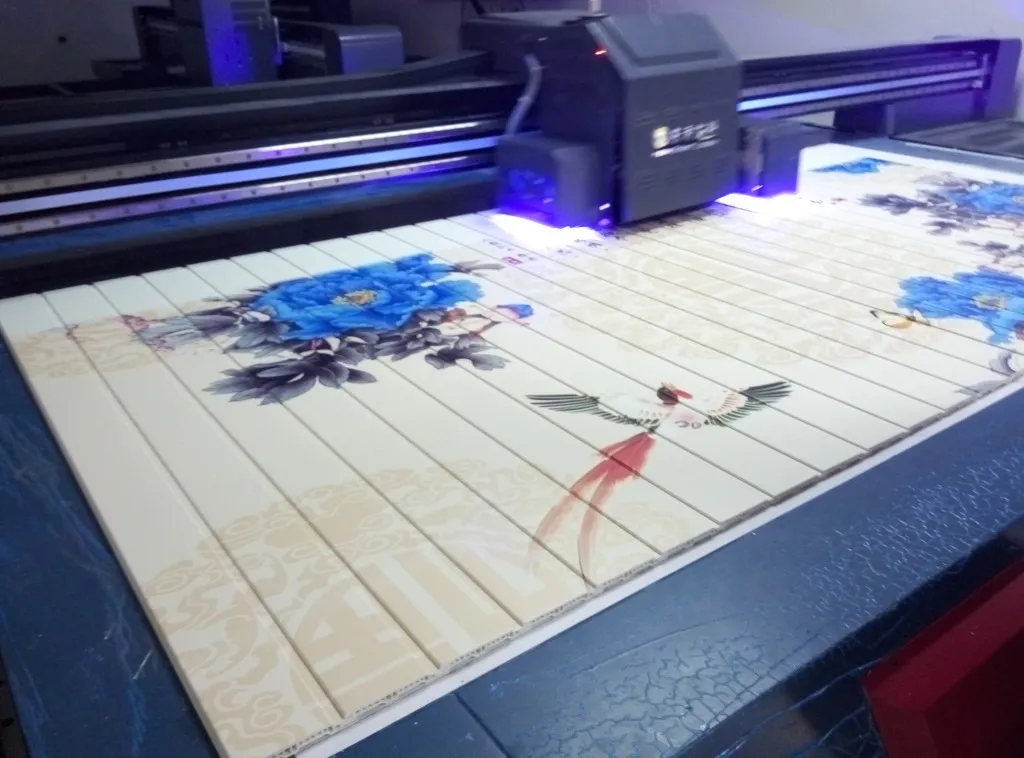

Flat UV Printing vs. Conventional Printing

principle

Flat panel UV printing: using piezoelectric inkjet printing technology, UV ink is directly sprayed onto the surface of the substrate through the nozzle, and then cured with a UV lamp for instant drying. Can apply on SEG light box, snap frame light box, acrylic sheet etc.

Conventional printing, such as offset printing, gravure printing, convex printing, etc., usually involves transferring ink from the printing plate to the substrate and then drying it.

Applicable materials

Flat panel UV printing: It can be printed on almost any flat material, including glass, metal, plastic, wood, leather, etc.

Conventional printing: There are certain restrictions on the printing materials, and some special materials may not be suitable.

Personalization level

Flat panel UV printing: It can achieve single piece printing, meet personalized customization needs, and does not require plate making.

Conventional printing: usually requires plate making, suitable for large-scale production, and has a relatively low degree of personalization.

Color expression

Flat panel UV printing: With bright colors and high saturation, it can achieve richer color combinations and transition effects.

Conventional printing: It has certain advantages in color accuracy and consistency, but may be slightly inferior in some complex color expressions.

Curing method

Flat panel UV printing: Instantly cured by UV lamp irradiation, with extremely fast drying speed.

Conventional printing: There are various drying methods, such as natural drying, hot air drying, etc., and the drying time is relatively long.

Environmental friendliness

Flat panel UV printing: UV ink is mostly environmentally friendly and emits less volatile organic compounds (VOCs).

Conventional printing: Some printing methods may use inks that have certain environmental pollution issues.

cost

Flat panel UV printing: The equipment investment is relatively high, and the production cost of single piece small batch is relatively high, but it has advantages in personalized customization and special material printing.

Conventional printing: equipment investment is relatively low, and the cost is lower when producing in large quantities.